CNC & 3D Printed Coaxial Belt Drive

Adapting an older metal chasis, use of a 3D printed belt system to add another degree of freedom for rapid prototyping and discovery.

Preferred 3D modeling software includes Fusion 360. Expertise in Autodesk Inventor, SolidWorks, Siemens NX, and AutoCAD Plant 3D. Designed and modeled a limited-slip differential gearbox for OSU's Baja Team, integrating parts with CNC machining and simulation for stress validation.

Learn more

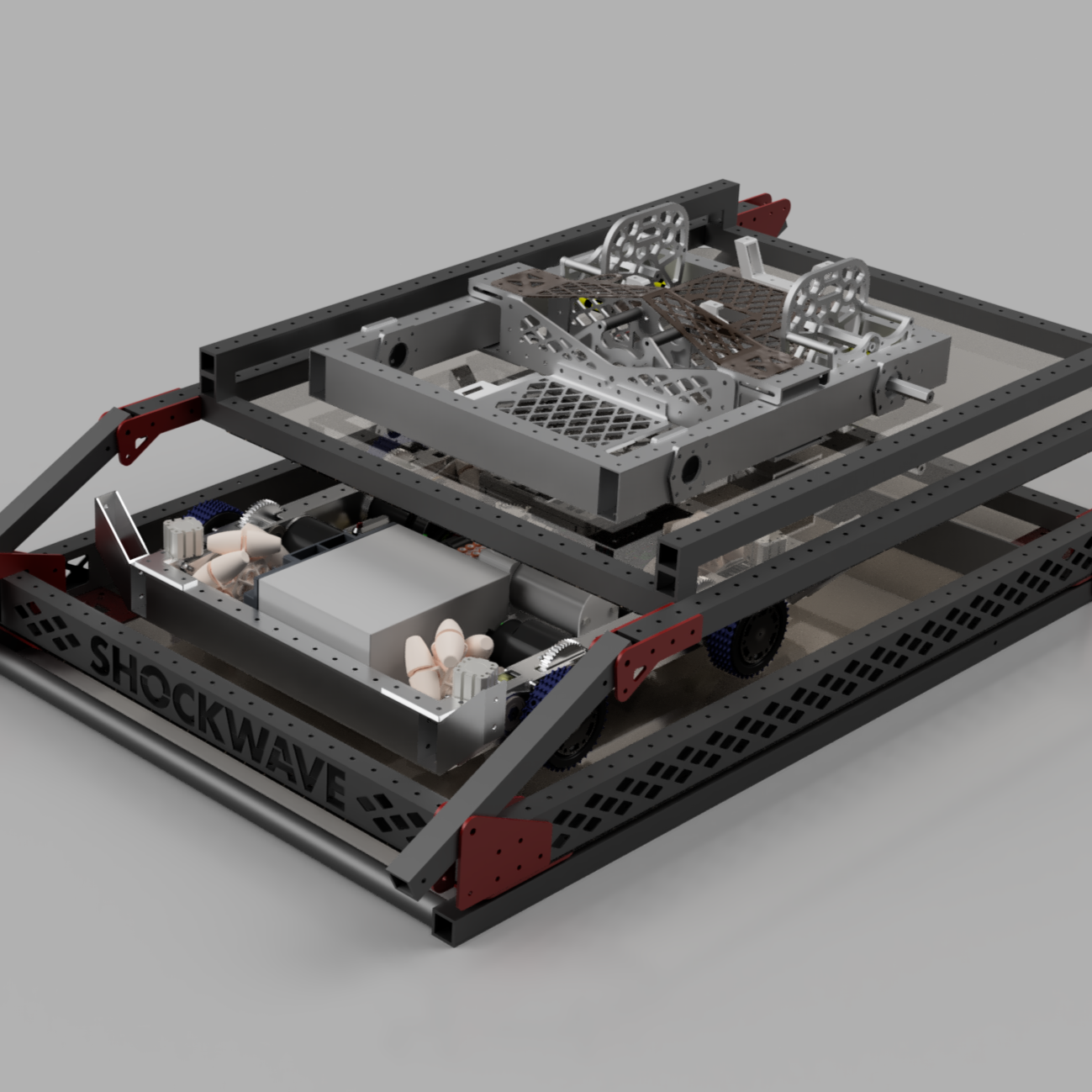

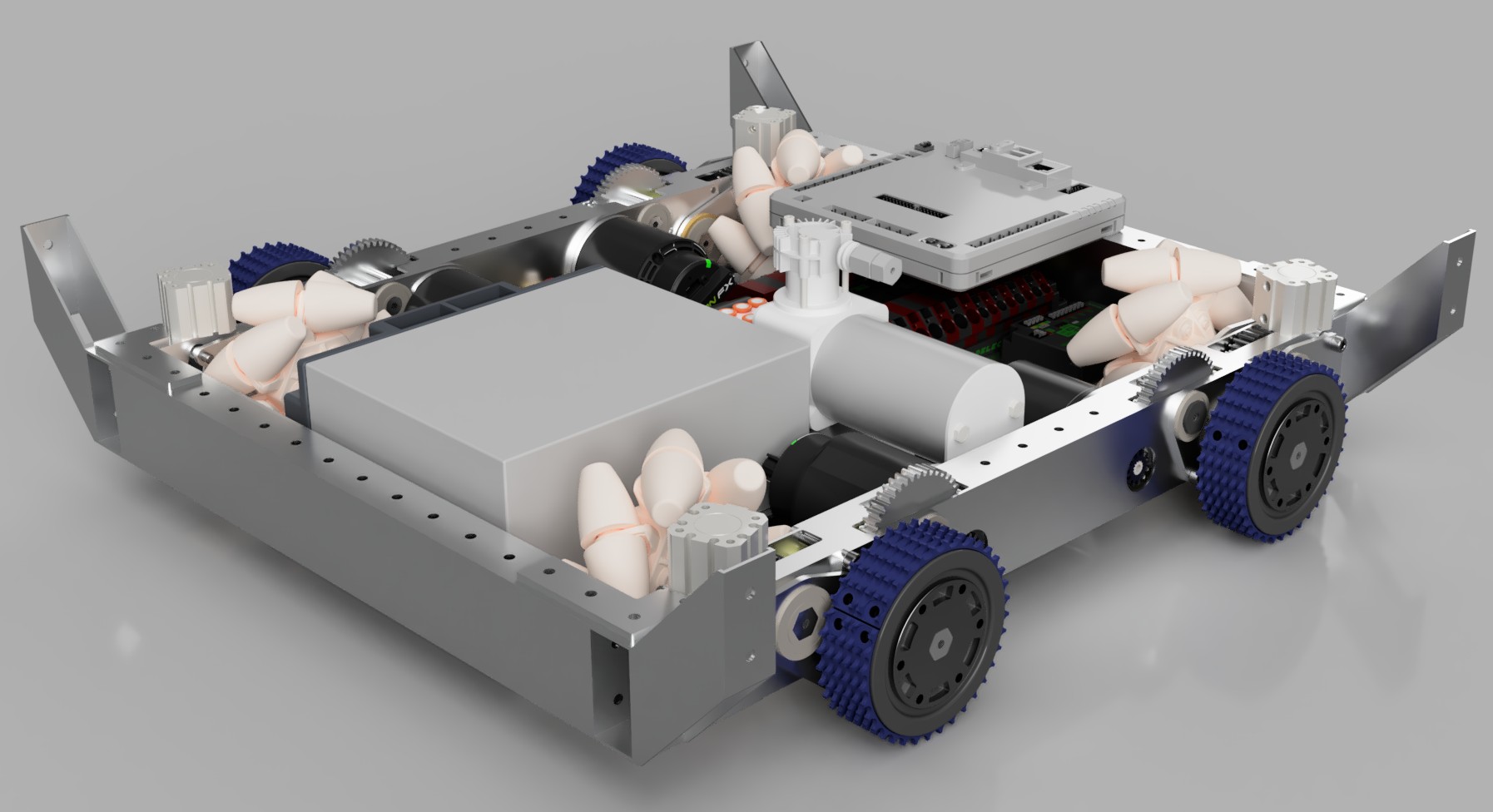

Led the mechanical team to design and prototype advanced robot systems, including swerve drive modules, mecanum shifters, and West Coast tank drives, contributing to Team 4488's successful participation in the FIRST Robotics Competition.

Learn more

Collaborated on cutting-edge robotics projects, including modeling origami spring hex bellows and developing odrive robotic controllers as part of my thesis on tethered projectile motion.

Learn moreAdapting an older metal chasis, use of a 3D printed belt system to add another degree of freedom for rapid prototyping and discovery.

Through use of Odrive motor controllers and CAN ROS2 control, this project was able to achive synchronized 2DOF movement to isolate the effects of angular momentum during a projectile throw.

Documented Github ultizing the ROS2 Package and an ESP32 Trigger with HTTP.

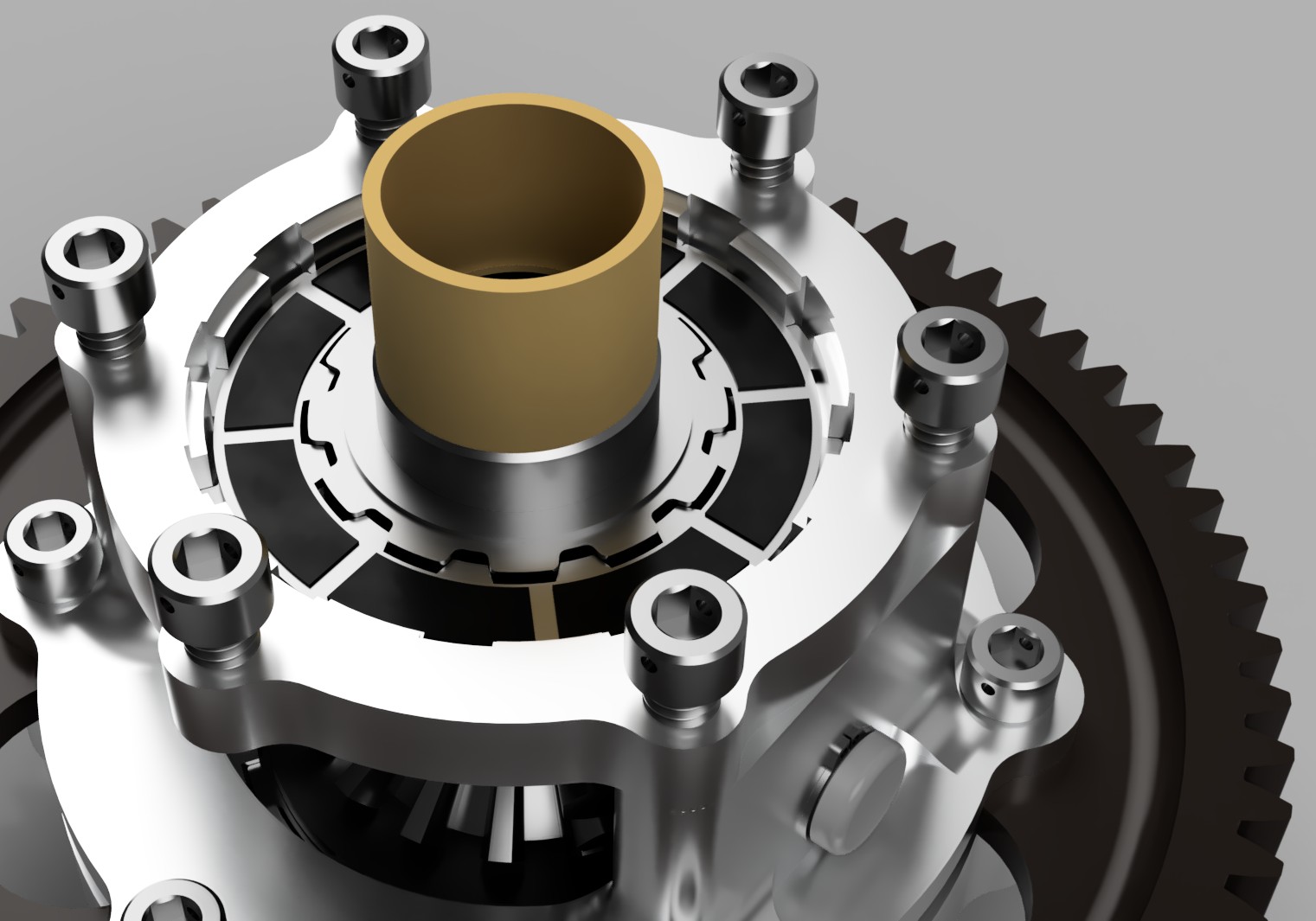

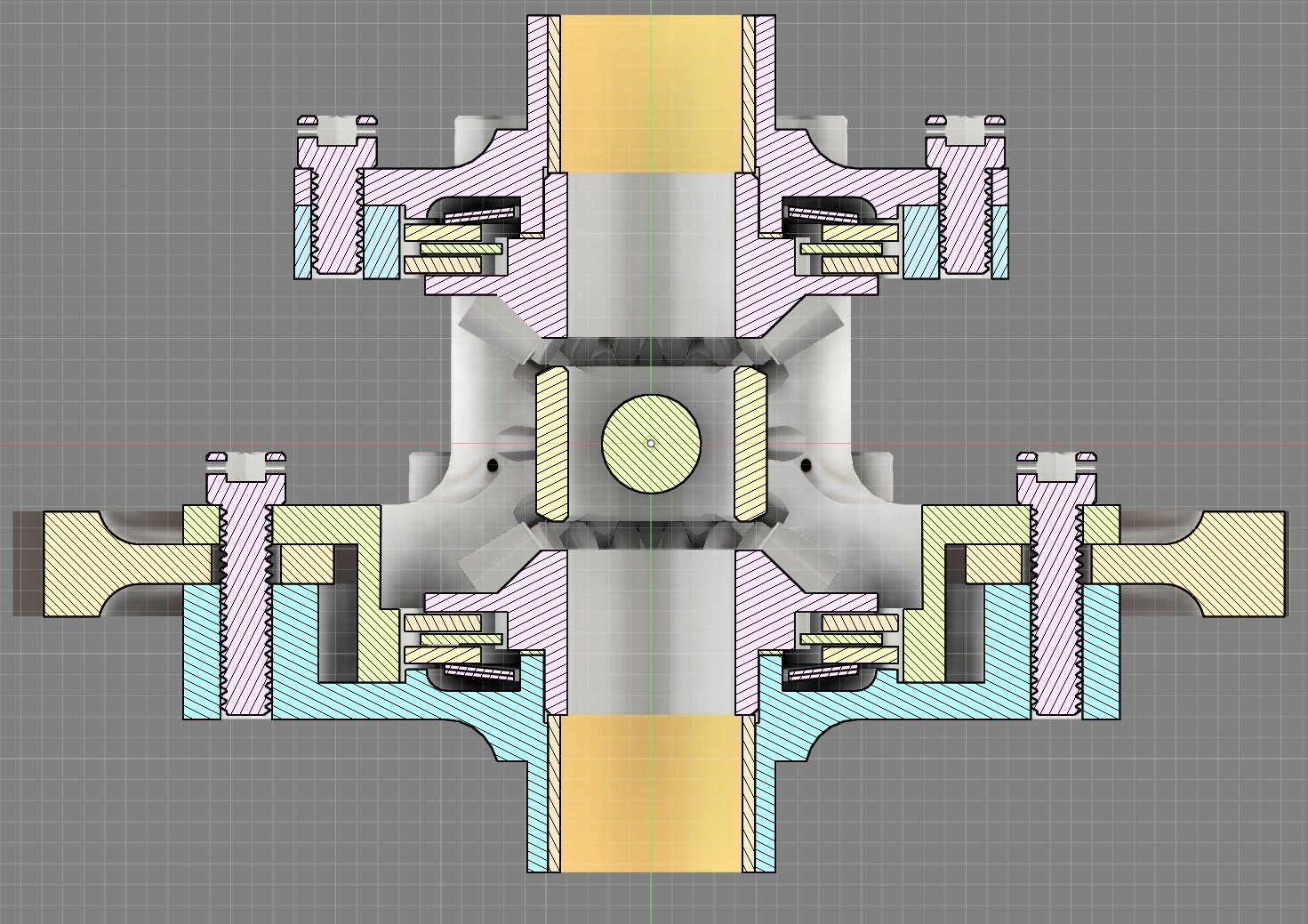

Redesigned a modified cast iron differential to a limited-slip differntial and an aluminum CNC body to be made in house and improve traction. This prevents one wheel from spinning out if at least one wheel has traction compared to a non-limited-slip.

Limited-slip is achived with custom plates with friction pads that compress together locking the gearbox. This compression occurs when the bevel gears expand due to high torque force, or a high torque imbance between the wheels.

As seen in the section view our module is precisely toleranced with interchangable disc springs for different slip torques.

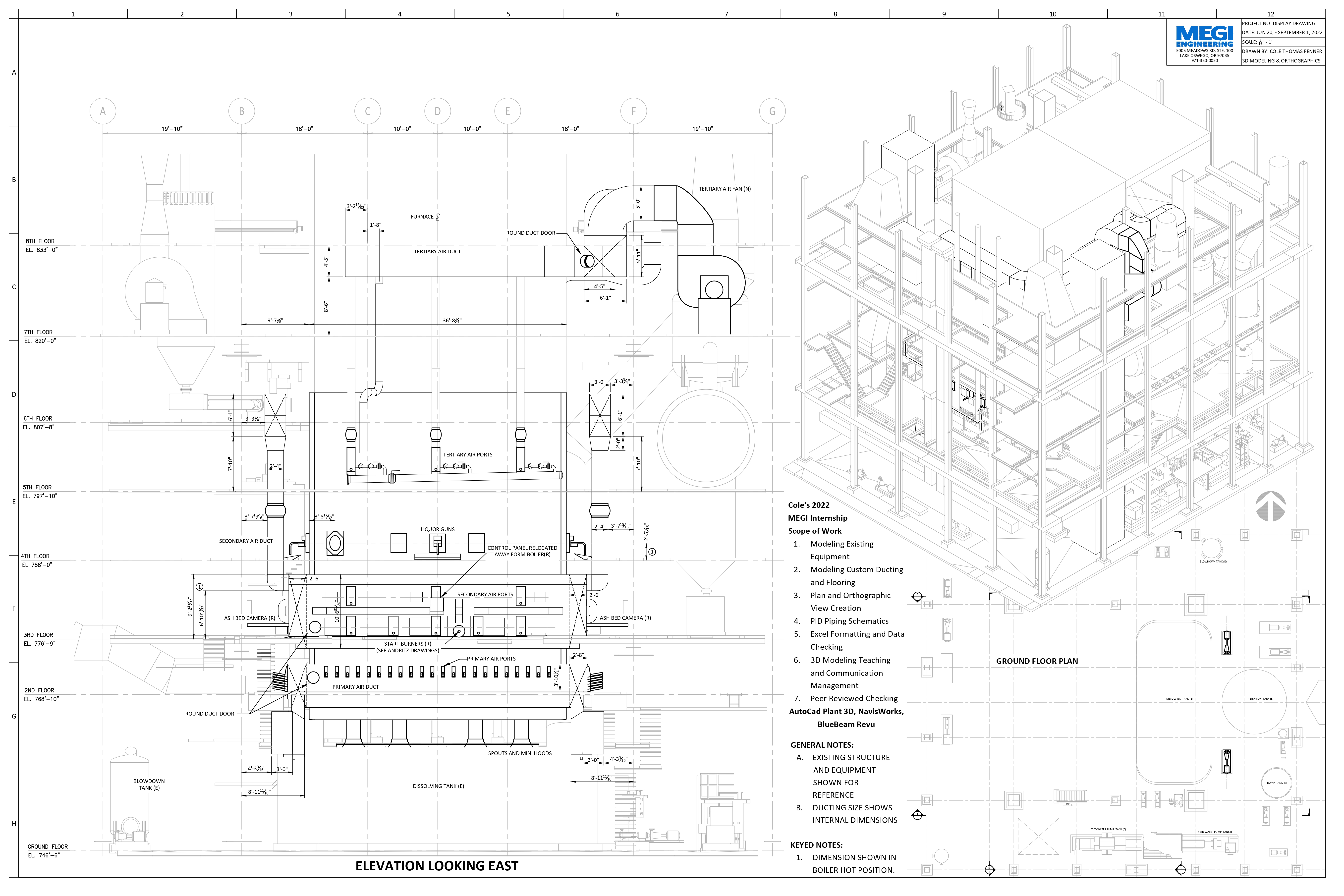

Developed 3D models in of industrial paper mill systems using point cloud data ultizing Navisworks, Bluebeam Revu, and AutoCAD Plant 3D.

Through these models created piping and eletrical systems in AutoCAD. (P&ID)

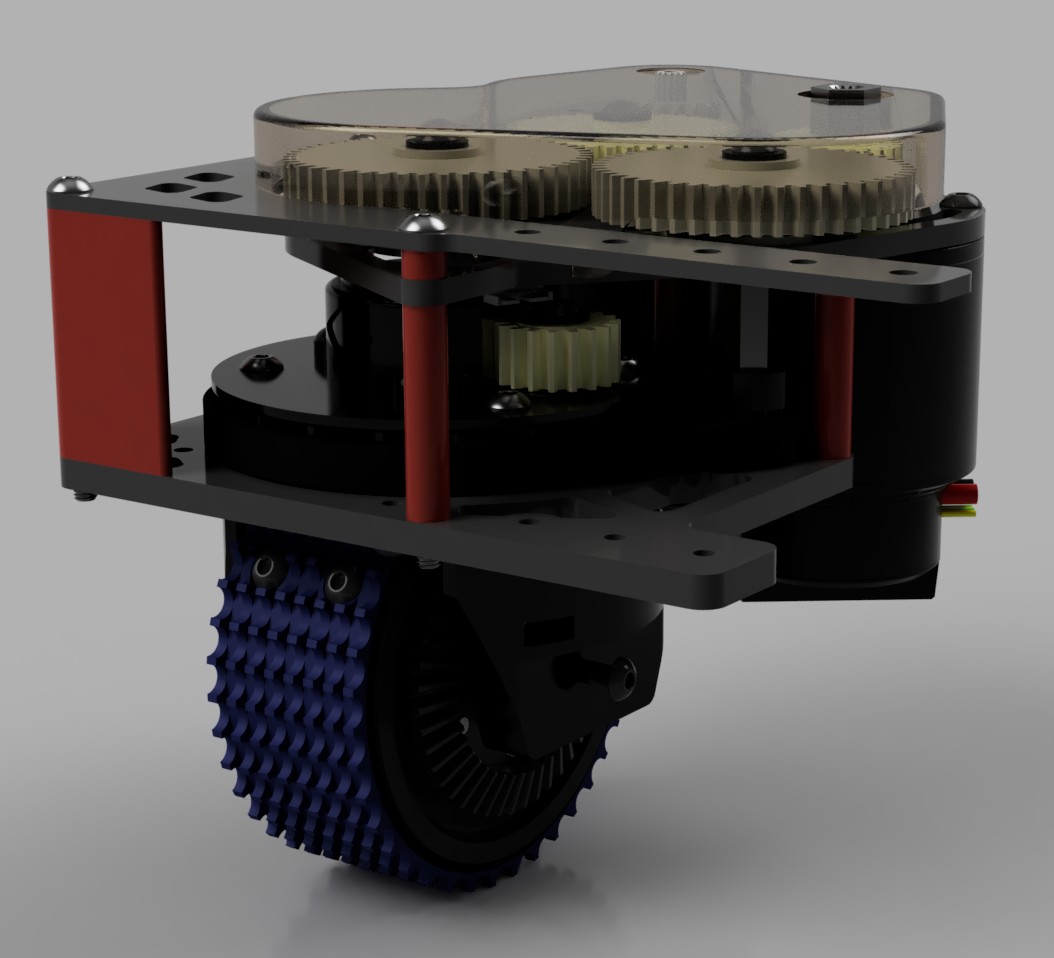

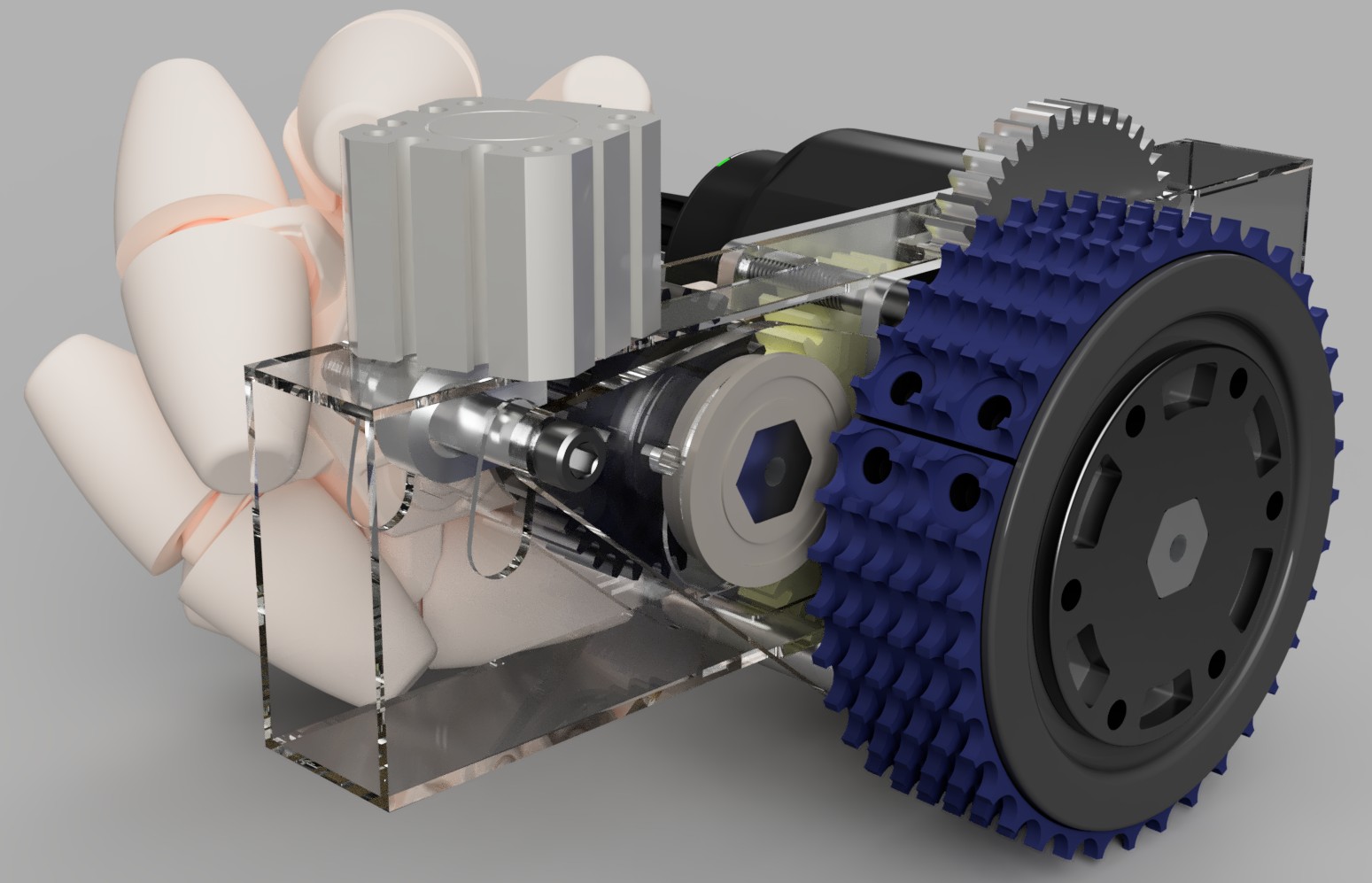

Two motor module drive system which allows each wheel to turn in place, enabling instantaneous movent in all directions. This is compact corner version is made from CNC metal, polycarbonate, and 3D printed parts.

A complete pneumatic system ultizied to "shift" between a mechanum and traction wheel. Designed gearbox inside a 2x1 bar for the most compact footprint of this drive module.